The automation of the biological treatment stage requires not only well-founded knowledge of automation but also a high degree of process engineering expertise about wastewater treatment and all associated process steps. Besides, the automation of biological processes requires highly complex algorithms that can only be realized approximately with "conventional" mathematics and programming.

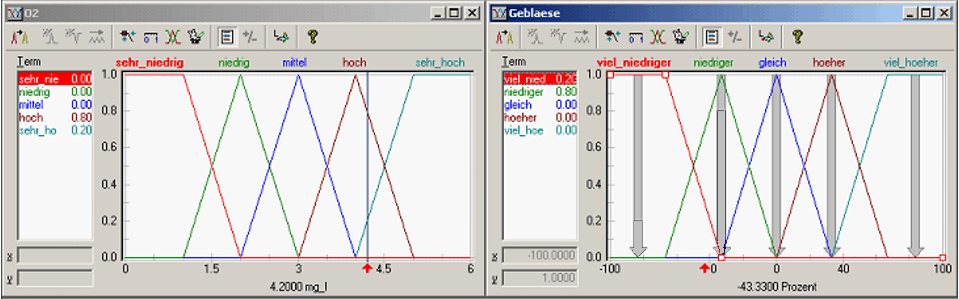

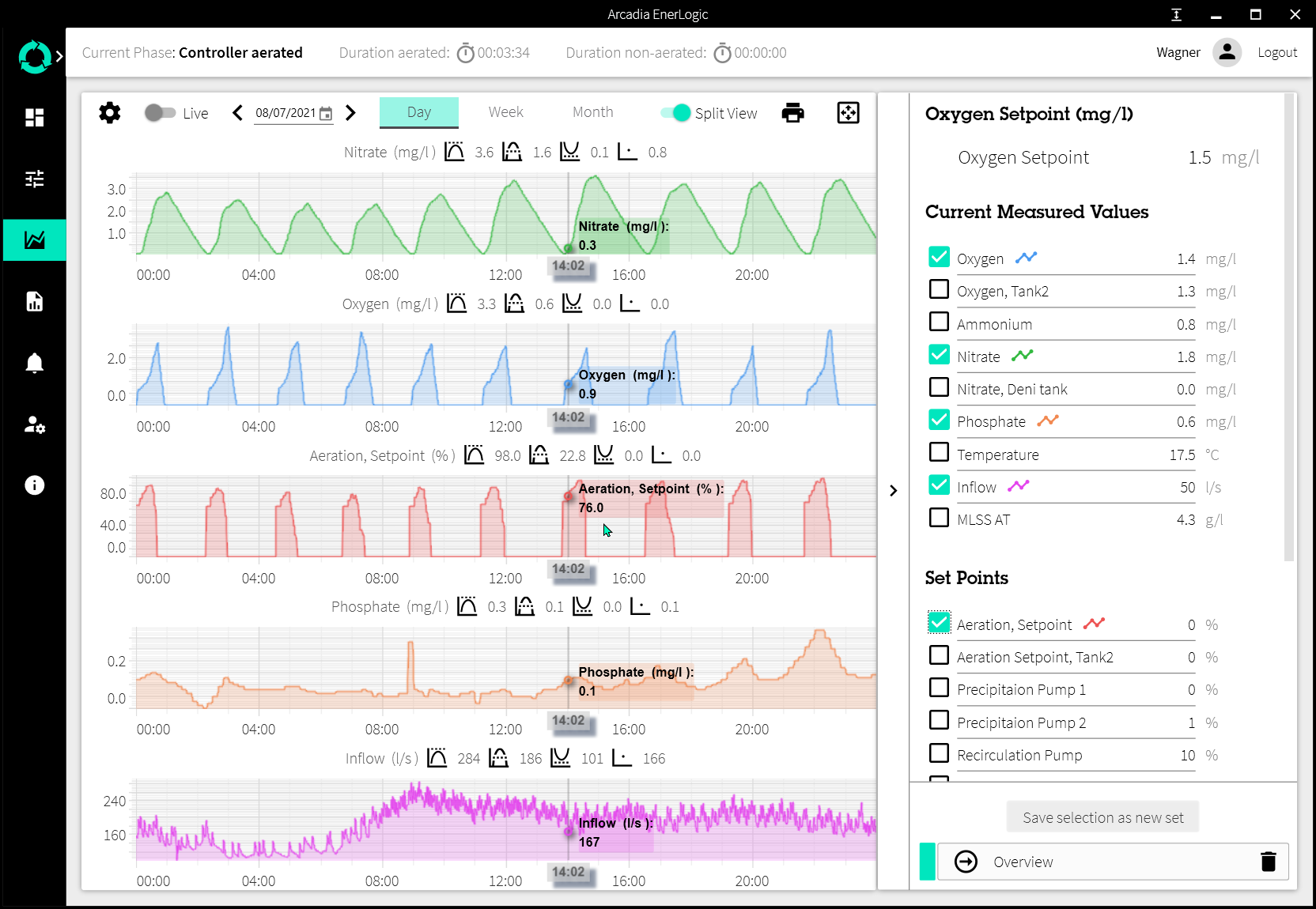

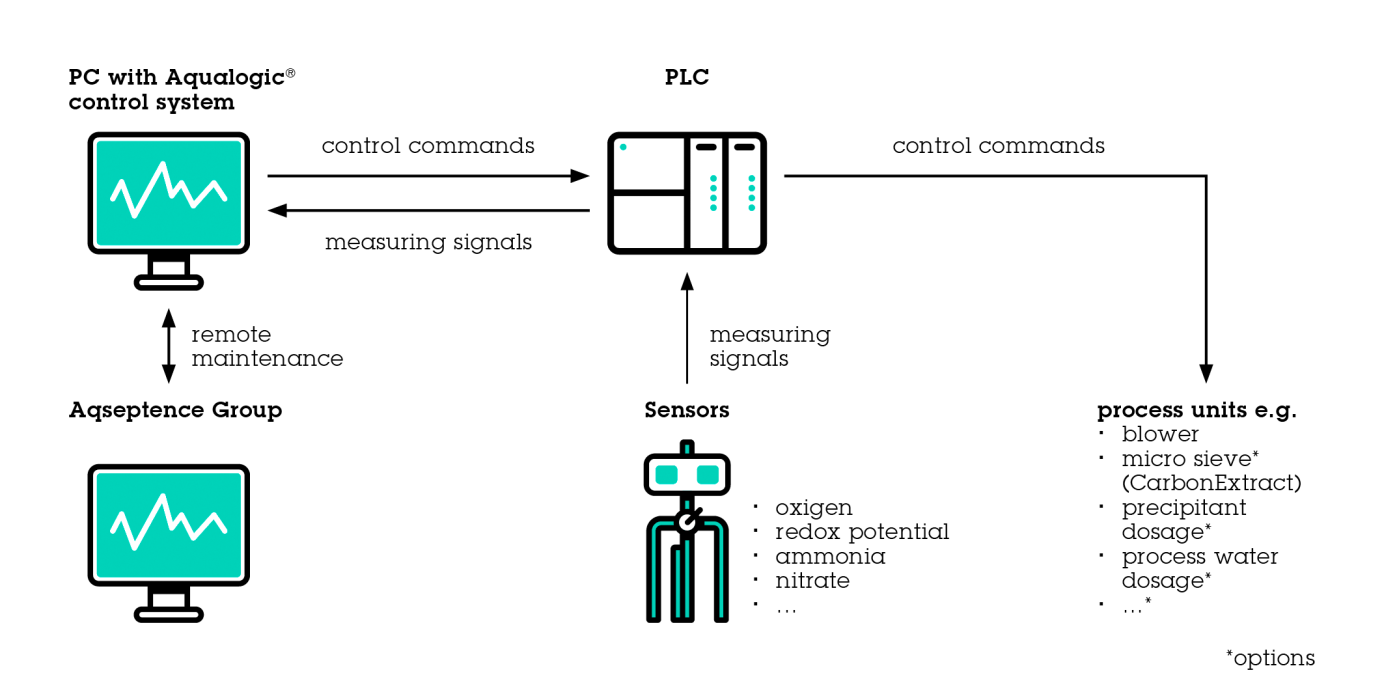

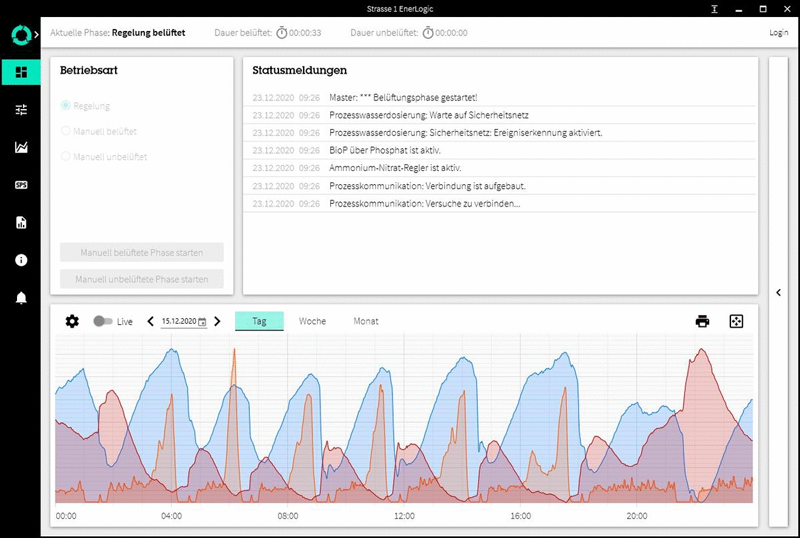

With Aqualogic® you have the software installed in several hundred wastewater treatment plants at your disposal which use Fuzzy Logic for the realization of control algorithms and thus can implement even highly complex non-linear multi-parameter algorithms. Thus, when using Aqualogic you always have the certainty that the necessary process knowledge is considered and applied during the realization of the automation and thus a stable plant operation is guaranteed in every situation.

Furthermore, Aqualogic can be flexibly adapted to changing requirements at any time, i.e. additional measuring probes or units to be controlled can be connected easily and without great effort or additional automation tasks or new modules can be added. We would be pleased to support you in designing the measurement and control concept for a current task and show optional extensions for future developments.

Thus, the planning reliability over all VOB performance phases is significantly increased by the use of Aqualogic®. We would like to inform you along with the VOB service phases how you and the end customer can benefit from Aqualogic®. An example is a fast implementation and commissioning (because it has been tested a hundred times), after which the operator can act independently immediately and no annoying program errors are to be feared later.